At its simplest form, food processing is the transformation of ingredients or food, and turning it in to other forms. The ingredients come into a facility raw and move through a physical or chemical change. The outcome is a product that marketable and distributed to other locations for sale. A simple example of food processing is yogurt. Raw ingredients like milk and sugar go through a chemical change through the use of bacteria. The bacteria use the ingredients to ferment the product and produce a new type of food. The new product is then packaged, shipped to grocery store and then consumed by buyers.

Food processing can be dated back to the prehistoric ages with the use of fermentation, sun drying, and basic cooking styles. With the use of slat preservation emerging in later civilizations, like the Greek, Egyptians and Roman civilizations, food processing adapted over the year. Over centuries and the introduction of industrial revolution, canning emerged upon the food processing scene. With the progression of the 19th and 20th century, additives and preservatives became popular. Salting seen in earlier civilizations developed to feed needs of the modern world. Food processing companies target the middle class and working mothers and technology, socio economic, and jobs change.

There are many benefits to food processing. The first benefit includes size and mass production. Batch processing is when larger amounts of ingredients are used to create large amount of food. Some products like condiments, sauces, pickles, and canned vegetables are perfect examples of batch production. Food processing is also beneficial to consumers because toxins are less likely to enter food, as well as products being less susceptible to early spoilage. By canning, and used additives products have longer shelf lives compared to raw products. Food processing is not a new concept. Food processing has humble beginnings that adapt over the centuries allowing for many different types of benefits

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

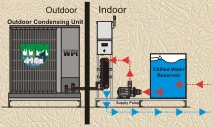

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |